Statistical Thinking

Statistical Process Control (SPC) for Everyone

28 hrs (full days or half days)

Course Overview

Statistical Thinking is a 7 part course comprising of 28 hours conducted in 3 and half days or 7 half days

The course is presented in a manner to enlighten both the newcomer to SPC as well as the seasoned engineer. Statistical Thinking is a valued skill that can dramatically improve the value of practitioners to the organization. One’s ability to quickly resolve problems and analyze data will be significantly enhanced and skills gained are easily transferable across products, processes, and industries.

This course covers the following topics:

- #1 Basic SPC pt 1

- Frequency Histograms

- Variable Control Charting

- #2 Basic SPC pt 2

- Attribute Control Charting

- Capability Basics

- Application to Projects

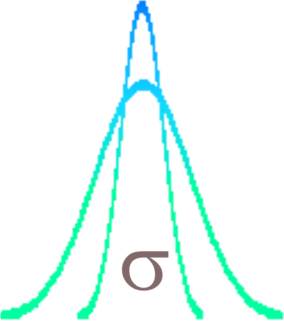

- #3 Process Capability

- Cp & Cpk

- Pp & Ppk

- Normality Testing

- Industry Guidelines

- Single Tailed & Folded Distributions

- Setting Specifications using Std Deviation

Topics Continued ...

- #4 FMEA

- Product Liability

- Probability Theorems

- Failure Rate

- System Definition Forms

- Flow charting

- Severity, Occurrence & Detection = RPN

- Corrective Action

- #5 Control Plans

- Control Plan Types

- Relationship to FMEA

- Zone Control Chart

- Narrow Limit Gauge Chart

- Control Plan development

Topics Continued ...

- #6 GR&R

- MSA – Definition

- Precision & Accuracy

- Bias – Stability – Linearity

- Repeatability

- Reproducibility

- Gauge R&R

- Attribute R&R

- #7 Acceptance Sampling Plans

- Types of Acceptance Sampling Plans available

- What they mean; Deciding on a LASP

- ANSI vs. Other types of ASP

- C=0 Plans

- Cost and Time Benefits

- How to Uses

Textbooks

- Learning to See: Value Stream Mapping to Add Value and Eliminate MUDA – Mike Rother

Target Audience

This course is suited for executives, lean practitioners, Kaizen facilitators, team leaders and managers that want to discover the waste streams within their processes and create organized work areas.

Learning Objectives

- Create Organized and efficient workplaces using the 5-S process

- Learn to maintain the 5-S gains through Visual Factory and Audits

- Develop skill with value stream maps to analyze the process in detail from the process participant’s and the customer’s viewpoints

- Learn value stream mapping as a critical skill to eliminating waste in the existing process

- Learn the features of different approaches to value stream mapping to enhance team learning

- Learn how to develop a detailed, data rich Value Stream Map

- Learn about some helpful mapping hints and how to use the maps in your events and planning processes